Director: Dr. Rupy Sawhney

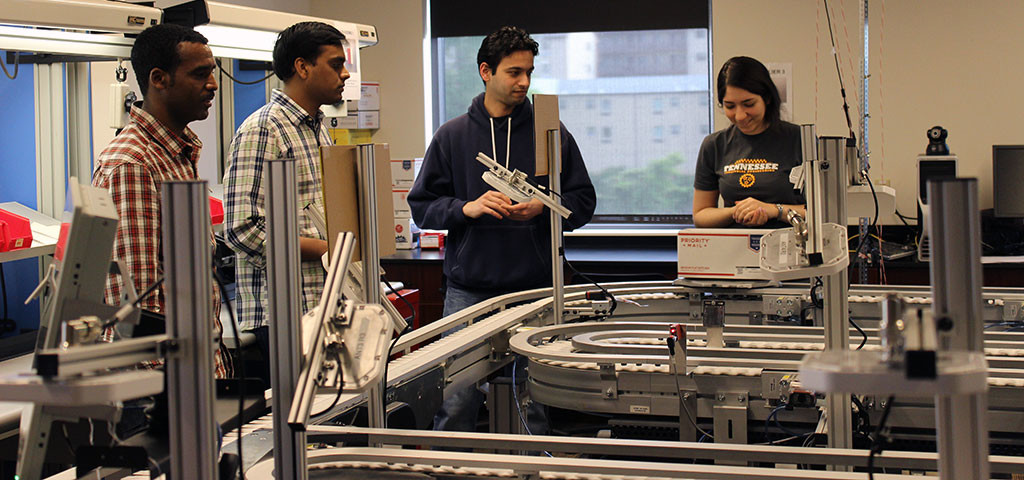

About the lab

The Factory Floor Lab is used for prototyping research ideas for virtual manufacturing environments. It is used in testing novel sensors for production processes, building a decision support system for manufacturing, and evaluating standard and novel operational metrics in production. The lab is a scaled representation of an assembly line production facility. It is equipped with a PLC-controlled central conveyor line with time delay loops, RFID and QR code readers, and workstations adjacent to the line.

Research

- Production fundamentals: A physical emulator for a production facility can be modeled using the hardware and software in the lab. This is used to study fundamental variables (e.g. cycle time, WIP) and metrics (e.g. utilization, efficiency) at various scales permitted by the setup, from the smallest, i.e. a single station, to the largest, i.e. a network of production stations.

- Sensing strategies: The lab serves as a test bed for the development and implementation of computer vision algorithms, which deliver reliable information about the location of products and personnel on the production floor. This setup has also been used to emulate material movement on factory floors and to compute risk metrics to prioritize the mitigation of hazards.

- Information models: The flow of information is modeled using a dashboard or simulated representation so that decision makers in charge of specific processes get relevant information. A ‘control room’ adjacent to the lab displays the information to the ‘decision maker’ to mimic virtual or remote factory floors.

Sample Publications

- Pradhan, N., Balasubramanian, P., Sawhney, R., and Khan, M. H. (2020) Automated risk assessment for material movement in manufacturing. Management and Production. To appear. 27(3).

- Thomas, T. (2019). A Capacity Model for Research Based Government Manufacturing Systems. Doctoral Dissertation. University of Tennessee.

- Venkatesan, B. (2017). Model for Prioritization of High Variation Elements in Discrete Production Systems. Doctoral Dissertation. University of Tennessee.